Автоматическая линия для изготовления штакетника забора Dura MPF11

Новая автоматическая линия профилирования для производства металлических заборов Dura MPF-1 AUTO

EVOLIUTIONER занимается производством, продажей и модернизацией металлообрабатывающего оборудования с 2001 года.

Это коллектив инженеров и квалифицированных специалистов: токарей, фрезеровщиков, сварщиков, слесарей и т.д.

Автоматическая профилегибочная машина для производства металлических заборов Dura MPF-1 Auto может стать эффективным решением для компаний, которые решили увеличить или начать производство металлических штакетников Durafence. Металлический штакетник это разновидность профиля, который можно получить путем прокатки плоского металла через прокатные ролики станка и в дальнейшем использовать в процессе изготовления и установки металлических заборов. Забор Дура (евроштакетник) имеет привлекательный внешний вид и может стать прекрасной частью любого дизайна, не скрывая его и не отягощая лишними элементами. Забор из дюралюминия станет отличным решением для строительства дома, дачи или любого другого строения.

Автоматическая профилегибочная машина для производства металлических заборов Dura MPF-1 AUTO полностью автоматизирована и может выполнять производственный процесс в полностью автоматическом режиме.

Технические данные:

Толщина металла 0,4 0,55 мм

Количество прокатных секций - 9

Мощность привода прокатного станка 1,5 кВт, 380 В (220 В)

Мощность гильотинного привода 1,1 кВт.

Мощность привода устройства для размотки жести составляет 2,2 кВт.

Скорость прокатки ~10 м/мин.

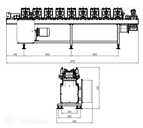

Размеры основной прокатной части 3000х800х1000 мм.

Вес основной подвижной части 510 кг.

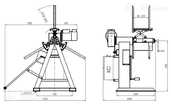

Габариты приспособления для разворачивания жести: 2200х1200х2000 мм.

Вес приспособления для разворачивания банки составляет 282 кг.

- Автоматическое устройство для размотки листового металла (размотчик) позволяет обрабатывать рулоны массой до 1,5 тонн и шириной до 350 мм. Размотчик помогает подавать металл на основную секцию прокатки, поэтому необходимо разместить рулон на валу размотки, отрегулировать внутренний диаметр рулона и поместить металл под компенсирующий механизм машины.

- Деталь прокатной машины, состоящая из прокатных роликов различного диаметра и конфигурации, предназначенная для прокатки металла и формирования необходимого профиля.

- Гильотинные ножницы для резки готовой продукции. Гильотина работает автоматически, поэтому заборы можно обрезать до необходимой длины и количества.

- Система автоматизации линии состоит из ручного пульта управления, автоматического пульта управления и стенда с экраном. Ручное управление позволяет перевести машину в ручной режим и протестировать ее перед автоматическим режимом работы. Пульт автоматического управления используется при работе линии в автоматическом режиме, что позволяет определять количество и длину формируемых изделий и программировать их раскрой по линиям.

Цена без доставки и пусконаладочных работ.

Гарантийное и послегарантийное обслуживание.

Возможен прямой плятеж заводу с НДС 0%.

https://stakles24.lt.....